Front Line Research

We delve keenly into the puzzle and mechanism of how deterioration and damage to metallic materials take place in a severe environment.

Understanding the mechanism of initiation, propagation, and retardation of stress corrosion cracking

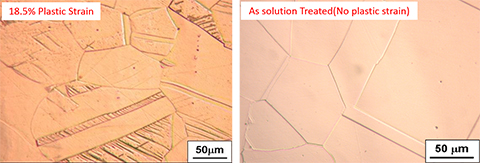

Low carbon stainless steel that is resistant to stress corrosion cracking is used in the primary cooling recirculation pipes in the boiling water reactors. Stress corrosion cracking is the phenomenon of cracks initiating and propagating in steel products due to a corrosive environment (high-temperature, high-pressure water, etc.) and static or dynamic load. Stress corrosion cracking has been experienced in a few pipes' welded joints during actual inspections of the power plants. For some reason, these cracks tend to stop propagation near the fusion lines of the pipes' welded joints.

Do stress corrosion cracks have the property to stop further cracking near the fusion lines of the pipes' welded joints? If they do, by shedding light on the reason for that property, we can derive standard criteria to evaluate the safety and lifespans of recirculation pipes. At the Watanabe Laboratory, we focused on the micro-structural characteristics of the fusion lines of the pipes' welded joints and have succeeded in unraveling the mechanisms of stress corrosion crack retardation. We can count on connecting our findings to the establishment of inspection methodologies for pipes' welded portions, as well as the development of new materials and technologies to prevent deterioration.